The first thing that most people look for in a solar panel is the wattage. No wonder, as it is normally the first piece of information depicted in a brochure or a datasheet. It’s not purely the best price per watt achievable that we should consider - there are a plethora of technical variables in solar modules that should be taken into consideration.

If you want to ensure you are delivering the right technology to your customers - helping to explain “total cost” and system yields outweighs any initial lower costings in procuring cheaper panels. More expensive panels with greater efficiency will ultimately contribute to lower electric bills – greater FiT or SEG payments in the UK, greater use of limited space and a greater time until any performance degradation.

The knock-on effect for your solar business is a positive impact on the preservation of margin and increased revenues for your business. In this blog post, we’re having a look at some of the important factors to be considered when offering a panel for a project.

Solar panel efficiency & usable space

Determined by the amount of irradiation which falls on a panel surface and is converted into electricity. Due to advances in solar cell technology, average panel conversion efficiency has increased from 15% to 20%. This has resulted in a common standard for panels to be around the 330W mark.

At the other end of the spectrum; there have been announcements recently from Trina Solar expanding on their 550W Vertex panel with plans for a 600W version in Q1 of next year and the LG Mono X PLUS (project panel) at 450W which is available now.

The LG Mono X PLUS key features:

• Cost-effective model designed for commercial projects

• BOS Saving cost due to lightweight during the installation

• Higher project profitability combined with LG Product Warranty (15 years) and Performance Warranty (25 years)

• Excellent yield performance with LG Product Quality.

• Design improvement for enhanced durability

• Half-cut Cells in 120 & 144 Cell format with improved electrical parameters

This product can only be considered for projects with a minimum size of 100 kWp per grid connection point.

Panel efficiency is determined by two main factors; the photovoltaic (PV) cell efficiency, based on the cell design and silicon type, and the total panel efficiency - based on the cell layout, wafer size, busbar configuration and panel size (footprint).

Often overlooked in the residential sales process, but vitally important to the efficiency and long-term reliability of a solar module, are its cells. The most common silicon material used is P-type or N-type. Cell efficiency is calculated by what is known as the fill factor (FF), which is the maximum conversion efficiency of a PV cell at the optimum voltage and current. There are few downsides for P-type cells use in residential applications, such as their susceptibility to light-induced degradation (LID), which is why you might see a first-year degradation allowance on modules of 3.0%.

Recent mono P-Type (PERC) cells and the latest heterojunction (HJT) cells have achieved efficiency levels well above 20%. It should be noted that even the colour of the panel protective backsheet can affect efficiency. A black backsheet might look more aesthetically pleasing, but it absorbs more heat and increases cell temperature, which in turn slightly reduces total conversion efficiency.

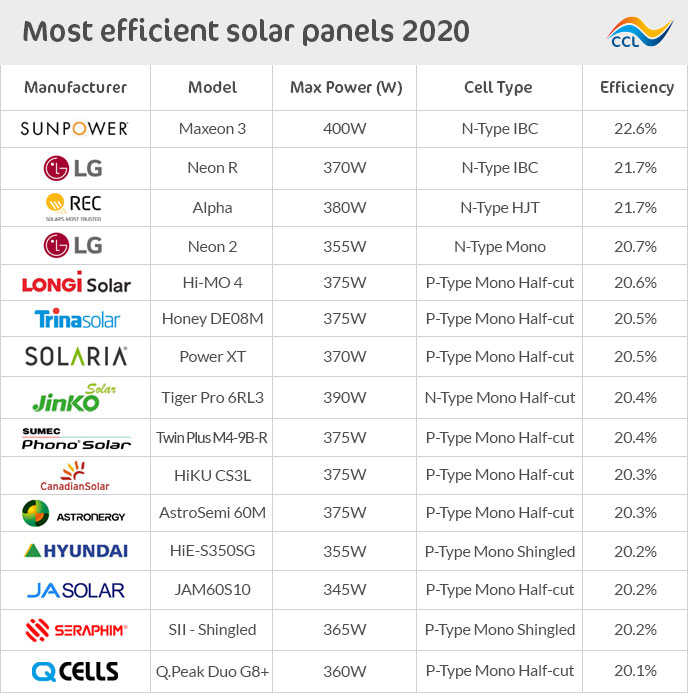

The most efficient solar panels on the market generally use premium N-type (IBC) silicon cells, such as those manufactured by LG. Panasonic is a well-known company using N-type (HJT) cells at scale. Most other manufacturers currently use the more common mono-PERC cells. However, several large volume manufacturers like Trina Solar are now starting to shift to the more efficient N-type cells. N-type and HJT modules allow for higher conversion efficiencies than P-type and due to chemical doping, experience very low LID. Although there is some first-year instability in performance, the first-year degradation allowance of these modules is typically no greater than 2.0%.

The final important factor to consider is that multi-busbar, or back contact modules such as LG’s NeON2 and NeON R respectively, are less susceptible to power loss if exposed to micro-cracking. This, along with physical and chemical properties, helps substantiate the lower warranted degradation rates of N-type and HJT modules.

Usable space

How much space do you have at your disposal and where is the space? Is it near the beach? You should then consider which solar panel has salt corrosion resistance on top of the efficiency rating.

More manufacturers are unveiling 66+ cell modules commonly have a larger footprint than the traditional 60 cell modules we’re used to. Again, it’s important to look past the upfront wattage rating. Module efficiency and ensuring the use of proper dimensions when laying out an array are going to then determine the value of your mounting equipment and the initial outlay cost of your proposed system. Smaller spaces call for panels with higher efficiency rating to utilise your space to its maximum.

Get in touch with CCL Components today to get our expert advice on solar panels and find out what's right for your project:

T: +44 (0) 1355 599 990

E: sales@blog.cclcomponents.com