The SolarEdge DC-optimised solution splits a traditional string inverter system into two parts: the Power Optimiser and the inverter. The Power Optimisers are located on each module – or each pair of modules - turning them into intelligent modules and providing module-level tracking and real-time current and voltage adjustments in order to allow each panel to operate at its optimum point. This topology brings with it a number of advantages over a traditional string inverter solution. Here we explain those differences and how they impact performance, design, safety and value in solar PV systems.

Performance

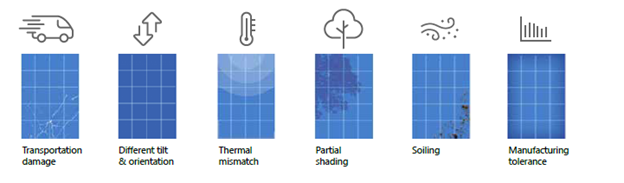

There are many external factors that can affect system performance, including: solar irradiation, module and ambient temperatures, solar incidence angle, module-ageing rates, shading and manufacturing tolerance. However, the impact on PV performance will depend on the type of inverter. All of these external factors cause each module in a string to have different Maximum Power Points (MPPs), which leads to module-level mismatch.

In a tradition string inverter system, module-level mismatch results in a decrease of PV generation, because the weaker module brings down the production of all the other modules in the same string.

By contrast, the SolarEdge DC-optimised system allows each module to produce at its own maximum power point, independent of the other modules in the same string. This approach to energy management eliminates power losses caused by module mismatch, meaning that the entire system can have increased solar production.

Here are the some of the common reasons for module mismatch:

Design & Balance of System Costs

A traditional string inverter system design requires all strings connected to the same inverter to be the same length, to use the same type of modules and to be positioned at the same angle towards the sun. This can result in wasted roof space or unnecessary duplication of components. The SolarEdge solution allows for longer strings, different tilts and different module types, enabling more flexible designs. Furthermore, by allowing longer strings within the design, the SolarEdge solution also enables savings of up to 50% on Balance of Systems costs, such as cabling and electrical components.

Safety

With millions of photovoltaic (PV) systems installed worldwide, this technology is designed to be relatively safe and reliable. However, as traditional PV installations can reach voltages as high as 1,500VDC, precautions should be taken to ensure the safety of people and assets. With traditional inverters, shutting down the inverter or the grid connection will terminate current flow, but DC voltage in the string cables will stay high for as long as the sun is shining. In addition, electrical arcs, which can result in a fire, create a threat to people and assets in the vicinity of the PV system.

The SolarEdge system provides a superior safety solution for both electrocution and fire risks.

SafeDC™

SafeDC™ is a SolarEdge built-in module-level safety feature which minimises electrocution risk.

To maintain string voltage below risk levels, power optimisers are designed to automatically switch into safety mode and the output voltage of each panel will be reduced to 1V:

- During installation, when string is disconnected from the inverter, or the inverter is turned off

- During maintenance or emergency, when the inverter or AC connection is shut down

The SolarEdge SafeDC™ feature is certified in Europe as a DC disconnect according toIEC/EN 60947-1 and IEC/EN 60947-3 and to the safety standards VDE AR 2100-712 and OVE R-11-1.

Arc-fault detection and interruption

SolarEdge inverters have a built-in protection designed to mitigate the effects of some arcing faults that may pose a risk of fire, in compliance with the UL1699B arc detection standard. Currently there is no comparable arc detection standard in the EU and therefore non-US SolarEdge inverters can detect and interrupt arcs as defined by the UL1699B standard. In addition to manual restart, a mechanism for auto-reconnect can be enabled during system commissioning.

System Monitoring

A traditional string inverter system cannot track performance down to a module level, making it impossible to identify module-level problems remotely.

In the SolarEdge system, monitoring sensors and transmitters are built into the SolarEdge Power Optimisers and inverters allowing measurement data to be transmitted to the SolarEdge Monitoring Platform. The Monitoring Platform is accessible 24x7 providing full visibility of the PV system's performance which in turn results in fewer visits to site and higher system uptime.